Learn about the intricate process of bronze casting, including the lost-wax method and modern casting techniques.

Bronze casting is a complex and intricate process that has been used for centuries to create sculptures, tools, and other objects. The lost-wax method is one of the oldest and most traditional methods of bronze casting, and it is still used by many artists and sculptors today. Modern casting techniques have also been developed, and they offer a number of advantages over traditional methods

Today, we will explore the lost-wax method and modern casting techniques. We will discuss the different steps involved in each process, and we will learn about the benefits and drawbacks of each method. We will also take a look at some of the most famous bronze sculptures that have been created using these techniques

So whether you are a sculptor, an artist, or simply someone who is interested in learning more about bronze casting, this article is for you!

The lost wax method, also known as investment casting, is a traditional and intricate technique used to cast bronze sculptures. This process has been employed for centuries and continues to be utilized today due to its ability to capture fine details and produce high-quality bronze artworks. Some of the Large bronze sculptures produced with this method include the famous “David” by Michelangelo, “The Thinker” by Rodin, and Henry Moore's “Reclining Figure”.

(Sculpted Rubber Wax)

The lost wax method involves creating a wax model of the desired sculpture, which is then used to create a mold. The wax model is later melted or "lost" during the casting process, hence the name "lost wax method." The resulting mold is filled with molten bronze to produce the final sculpture.

The first step in the lost wax method is creating a wax model of the sculpture. Skilled artisans sculpt the wax, carefully refining and detailing every aspect of the artwork.

Once the wax model is complete, it is coated with a heat-resistant ceramic material. This creates a ceramic shell around the wax, forming the mold for the bronze casting. The shell is built up in layers, allowing it to withstand the high temperatures of the molten bronze.

The ceramic shell is then heated, causing the wax to melt and flow out, leaving behind an empty space within the mold. This step is crucial as it creates the negative space necessary for the bronze to fill.

Molten bronze, heated to a specific temperature, is poured into the ceramic mold. The bronze fills the void left by the melted wax, taking the shape of the original sculpture.

Once the bronze has cooled and solidified, the ceramic shell is carefully broken or chipped away, revealing the rough-cast bronze sculpture. The sculpture then undergoes further refining, polishing, and patination to achieve the desired appearance.

(Finished product)

The lost wax method requires several materials, including sculpting tools, wax, heat-resistant ceramic materials, kilns or furnaces for heating, crucibles for melting bronze, and various tools for finishing and refining the cast bronze sculpture.

The lost wax method is a time-honored and highly respected technique for casting bronze sculptures. Its ability to capture intricate details, replicate sculptures, and achieve excellent artistic results has contributed to its enduring popularity. Despite its labor-intensive nature and associated costs, the lost wax method remains a preferred choice for artists seeking to create exquisite and lasting bronze sculptures. Whether it's a small bronze artwork or a large bronze statue, the lost wax method continues to shape the world of bronze sculpture, providing artists and collectors with remarkable works of art for generations to come.

Modern casting techniques have revolutionized the process of casting bronze sculptures, offering artists new possibilities for creativity and efficiency.

Modern casting techniques refer to contemporary methods employed in the casting of bronze sculptures. These techniques often utilize advanced technology and materials to streamline the casting process and enhance artistic possibilities.

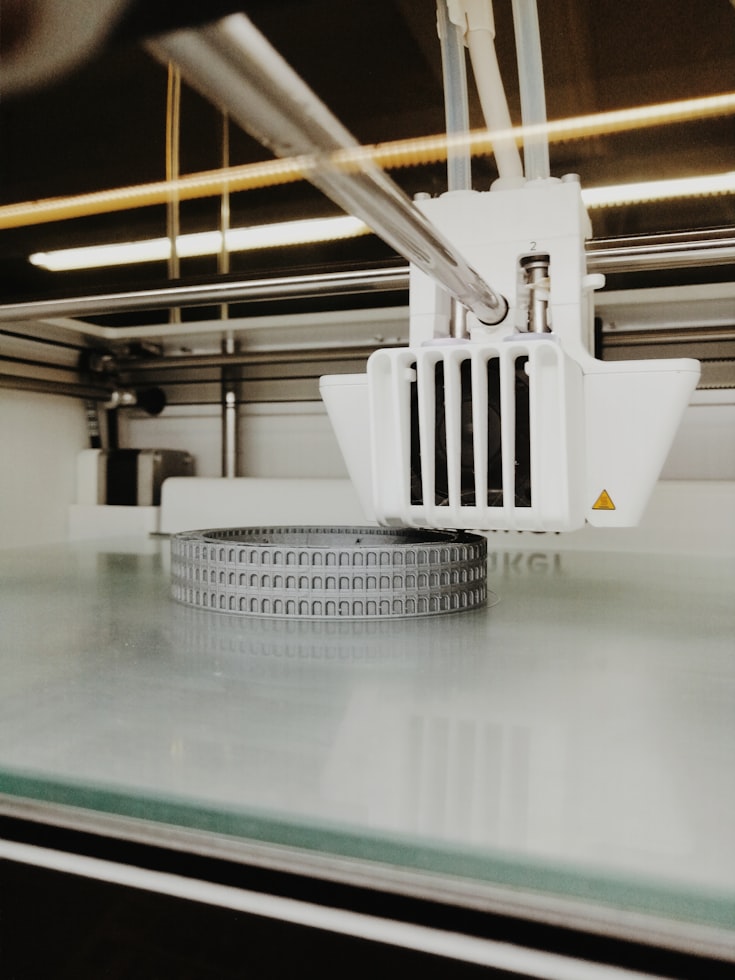

One modern technique involves the use of 3D printing technology. Artists can create intricate digital models of their sculptures using computer software. These digital models are then printed using specialized 3D printers, producing a physical replica of the sculpture in wax or other materials.

Once the 3D printed model is ready, it is used to create a mold. The mold can be made from various materials, such as silicone or rubber. The mold captures the form and details of the sculpture and acts as a negative space for the molten bronze.

Molten bronze is poured into the mold, filling the negative space left by the 3D-printed model. The bronze cools and solidifies, taking the shape of the sculpture. After cooling, the mold is removed, revealing the cast bronze sculpture.

The cast bronze sculpture goes through additional refining processes, including removing any imperfections, polishing the surface, and applying patinas or finishes to achieve the desired appearance.

Modern casting techniques require materials such as 3D printing materials (e.g., wax or resin), mold-making materials (e.g., silicone or rubber), molten bronze, refining tools, polishing materials, and patination agents.

Modern casting techniques have opened up new possibilities in the world of bronze sculpture. Through 3D printing and advanced mold-making processes, artists can achieve greater precision, time efficiency, and replicability in their bronze casting endeavors. While the cost and technical expertise associated with modern techniques may present challenges, the advantages they offer in terms of artistic potential and production efficiency make them a valuable addition to the realm of bronze sculpture. As technology continues to evolve, these techniques will likely continue to shape the future of casting bronze sculptures, offering artists and collectors a wide range of stunning and innovative artworks to appreciate and acquire.

The time required to cast a bronze sculpture varies depending on factors such as size, complexity, and the chosen casting method. Generally, the process can take several weeks, involving stages like mold-making, wax work, ceramic shell creation, bronze pouring, and finishing. However, the precise timeframe is influenced by the individual project's intricacies and the artist's expertise. A bronze sculpture studio such as Marbleism could cast a large bronze sculpture for 10 days

Bronze casting is typically a specialized process that requires specialized equipment, knowledge, and facilities. It involves working with high temperatures and molten metal, which can be dangerous without proper safety measures. While some small-scale casting can be done at home with proper precautions, larger and more complex bronze casting projects are typically best left to professional foundries with the necessary expertise and resources. The best suggestion would be to contact Marbleism bronze studio and get your ideal bronze statue customised in a few weeks and delivery to your door.

Yes, working with molten bronze poses several health and safety considerations. The high temperatures involved can cause severe burns, and proper protective clothing, including heat-resistant gloves and aprons, should be worn. Adequate ventilation is crucial to prevent inhalation of harmful fumes. Additionally, safety protocols should be followed for handling and pouring molten metal, including using appropriate tools and equipment, and working in a controlled environment to minimize risks.

Bronze sculptures are highly durable and known for their longevity. Bronze is a strong and resilient material that can withstand various environmental conditions, including exposure to outdoor elements. With proper care and maintenance, bronze sculptures can retain their beauty and structural integrity for centuries. Regular cleaning, protecting against corrosion, and periodic maintenance can help preserve the durability and appearance of bronze sculptures over time

Yes, bronze sculptures can be displayed outdoors. Bronze is a durable material that can withstand exposure to the elements, making it suitable for outdoor settings. However, it's important to consider factors such as weather conditions, UV exposure, and maintenance requirements. Applying a protective coating and periodic cleaning can help preserve the sculpture's appearance and longevity when displayed outdoors.

Yes, there are various finishes and patinas that can be applied to bronze sculptures to achieve different aesthetics and effects. Patinas are chemical or heat-induced surface treatments that can alter the color and texture of the bronze. They can create effects such as darkening, aging, or creating vibrant hues. Common patinas include traditional browns, greens, and blues, but artists can experiment with a wide range of colors and textures to achieve their desired look. Additionally, artists can choose to leave the bronze sculpture with a natural or polished finish, depending on their artistic vision

In conclusion, when considering the casting of bronze statues for sale or large bronze sculptures, both the lost wax casting process and modern casting techniques offer distinct advantages. The lost wax method preserves tradition and allows for intricate detailing, capturing the essence of classical craftsmanship. On the other hand, modern casting techniques, such as 3D printing, provide efficiency and replicability, facilitating the production of multiple sculptures. The choice between these methods depends on the desired outcome, artistic vision, and practical considerations. Ultimately, both techniques contribute to the diverse and vibrant world of bronze sculpture, offering collectors a wide range of captivating artworks to admire and acquire. Email The Marbleism Studio and get a bronze scultpor’s suggestion for your garden project .

Drawing of Fountain